R&D Team

Wampolet boasts a highly experienced R&D team specializing in thermal-sensitive coatings, film top-coatings, and specialty new materials. Comprised of technical experts with backgrounds in chemical engineering, pulp and paper making, polymer materials, and printing engineering, the team is committed to research and development of specialty materials, guiding Wampolet towards sustainable development through innovation.

Over the past decade, Wampolet has made a significant leap from producing standard thermal papers to specialty thermal materials. In 2019, Wampolet started top-coated film production and successfully launched synthetic paper and pearlescent films onto the market. Today, Wampolet holds a leading position in the industry in terms of technology, market share, and customer recognition. Facing fierce market competition, we adhere to the principle of customer service and define our R&D strategy:

Improve the performance and stability of existing products, thereby reducing costs and enhancing efficiency to deliver more value to customers

Utilize core technological capabilities to develop specialty products, providing customized services to customers

Expand product types, enrich product structures, achieve product diversification, and broaden the business service scope

R&D Laboratories

This facility is dedicated to testing and evaluating the physical and chemical properties of coatings. It analyzes various data indicators of material coatings to determine their functional performance.

• Dispersing and Grinding Machine

• Surface Tension Tester

• Moisture Tester

• Melting Point Tester

This lab is utilized for analyzing and dissecting the coating structures of products to perform analyses on a variety of substances. It effectively identifies the authenticity of materials through infrared spectroscopy.

• Fourier Transform Infrared Spectrometer (FTIR)

• Metallurgical Microscope

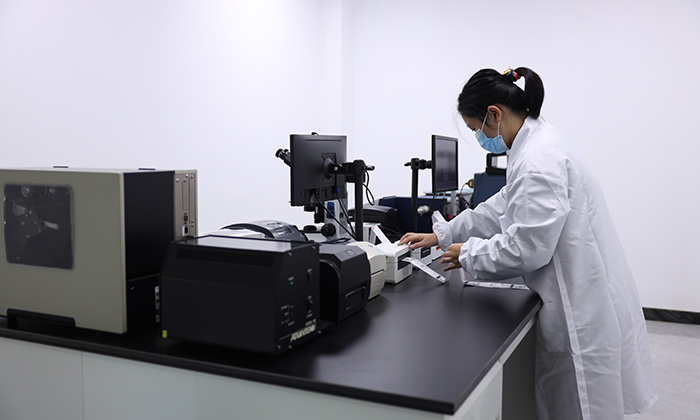

This lab is used to evaluate the printing performance of functional materials to ensure that our products are suitable for various printing methods and maintain good printability during the conversion process.

• Flexographic Proofing Press

• Offset Proofing Press

• UV Dryer

Dedicated to assessing the variable information printing performance of materials to ensure compatibility with popular printers on the market and to achieve clear printing results.

• 1D/2D Barcode Reader

• Dynamic Chromogenic Instrument

• Thermal Printers

• Thermal Transfer Printers

Simulates a variety of application environments to test and evaluate the weathering resistance of products, ensuring that they meet customer’s specific application requirements.

• Humidity Aging Chamber

• Reflective Density Meter

Used to test various physical performance indicators of products under constant temperature and humidity conditions, such as material strength, stiffness, and dimensional stability, and providing a scientific theoretical basis for the product performance.

• Intelligent Electronic Tensile Tester

• Paper Tear Tester

• Paper Air Permeability Tester

R&D Achievements

2012

Developed water-resistant thermal paper without BPA to satisfy market sustainability requirements

2013

Developed thermal paper with properties of waterproofness, oil resistance, and high-temperature resistance, enriching the thermal paper product line

2014

Further enhanced the performance of thermal paper in waterproofing, oil resistance, alcohol resistance, heat resistance, and scratch resistance; Produced high grammage thermal cardstock for applications in boarding passes and clothing tags, etc.

2015

Developed and launched lottery thermal paper in the market; Collaborated with a famous domestic express company to develop thermal printing waybills for express delivery

2016

Successfully developed and commercialized thermal film, filling a domestic void and reducing reliance on imported products

2018

Collaborated with a renowned domestic express company to develop thermal film for cold chain logistics

2019

Launched label film products and phenol-free thermal film in response to global environmentally friendly initiatives

2022

Developed a high-temperature resistant thermal film for use in hot drink and bento labels; Successfully developed alcohol-resistant thermal paper for medical applications, addressing the need for anti-epidemic labels

2023

Successfully developed thermal film for medical B-ultrasound report printing applications

Patent Acquisition

In the field of thermal functional materials, we persist in our dedication to innovation in production technologies, optimization of process workflows, enhancement of product performance, and the development of new products. As of now, we have successfully obtained 15 invention patents, 51 utility model patents, and 38 software copyrights. These achievements not only affirm our expertise but also highlight our industry-leading status. Our pursuit of innovation is ongoing, with more patents and software copyrights pending to deliver further breakthrough solutions.

Invention Patent Certificate

Utility Model Patent Certificate

Cooperation Projects

To enhance innovation and R&D capabilities, Wampolet actively engages in technical exchanges and cooperation with universities, research institutions and industry leaders while insisting on independent innovation.

★

Collaborated with universities, e.g. Jiangsu University of Science and Technology, to establish an integrated industry-university-research R&D framework that provides strong support for our R&D capabilities

★

In partnership with the National Engineering Laboratory for Pulp and Paper, we have established the "National Engineering Laboratory for Pulp and Paper Wampolet Thermal Paper R&D Center"

★

Initiated close cooperation with renowned domestic and international enterprises in various industries to drive R&D innovation

Business Connection

E-mail: info@wampolet.com

Address: No. 86 of Wufengshan Road, Zhenjiang Economic and Technological Development Zone, Jiangsu Province